alternateur à aimant permanent pour turbine hydraulique

Description du produit

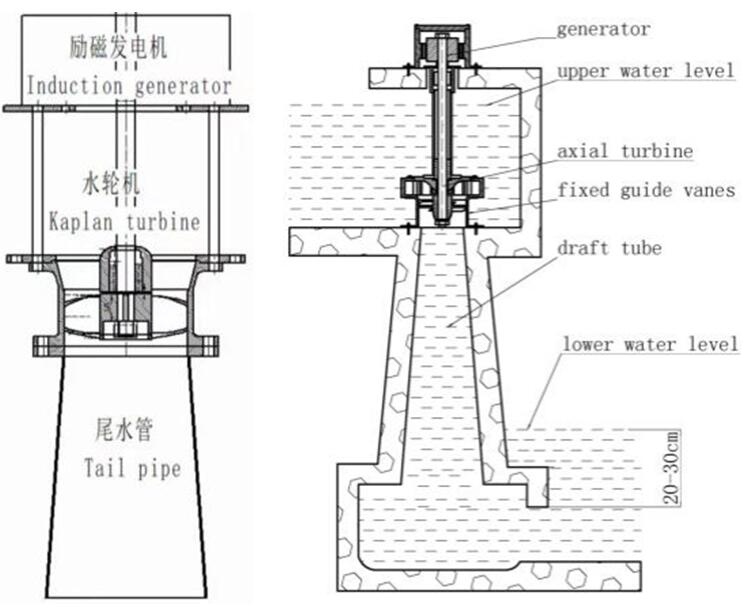

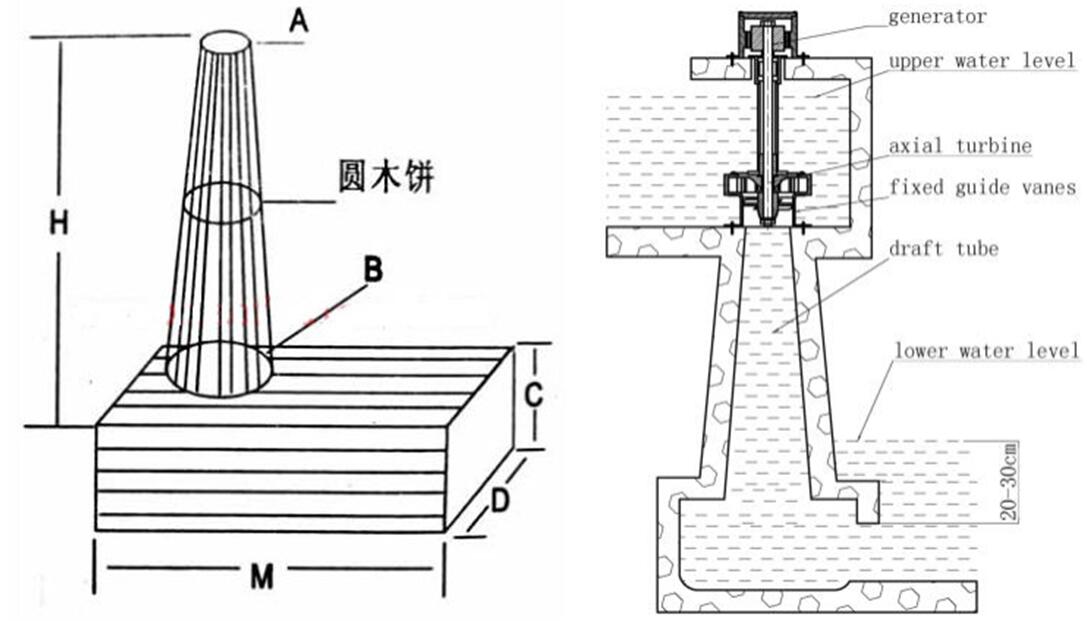

Le générateur hydroélectrique axial à canal ouvert est composé d'une microturbine hydraulique axiale et d'un générateur montés sur un seul arbre. La turbine hydraulique comprend principalement une aube directrice d'entrée, une roue à aubes rotative, un tube d'aspiration, un arbre principal, un socle, des paliers, etc. Lorsque le fluide à haute pression est acheminé dans le tube d'aspiration, un vide se crée. L'eau en amont, guidée par le canal d'entrée et la volute, pénètre dans l'aube directrice et entraîne la rotation du rotor.

Par conséquent, l'énergie de haute pression et l'énergie dynamique à haute vitesse sont transformées en puissance.

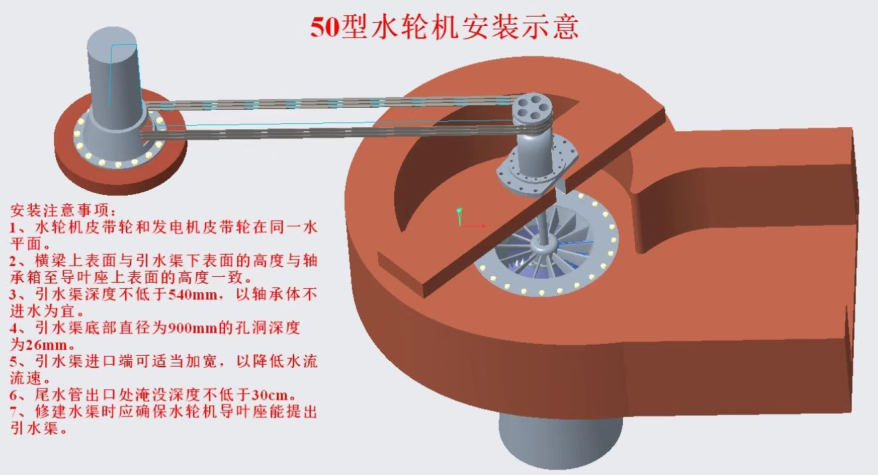

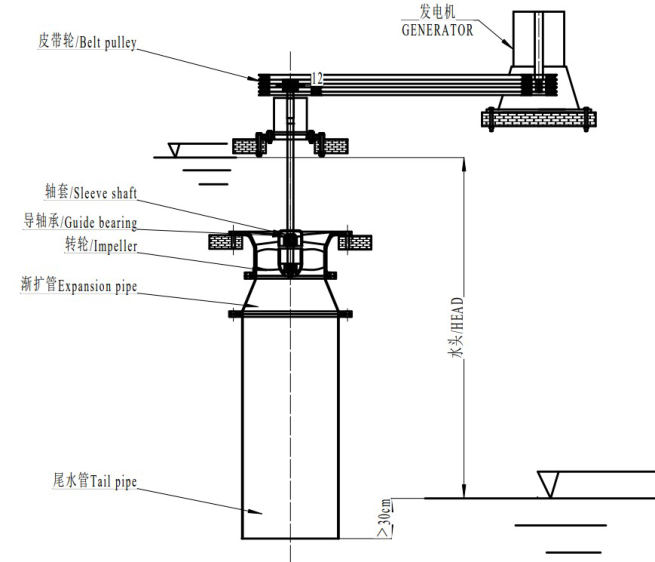

Schéma et plan d'assemblage d'une turbine axiale à canal ouvert

Schéma et plan d'assemblage d'une turbine axiale à entraînement par courroie

Le groupe électrogène vertical à canal ouvert et à flux axial est une machine tout-en-un présentant les avantages techniques suivants :

1. Léger et de petite taille, il est facile à installer, à transporter et à entretenir.

2. La turbine possède 5 paliers, ce qui la rend plus fiable.

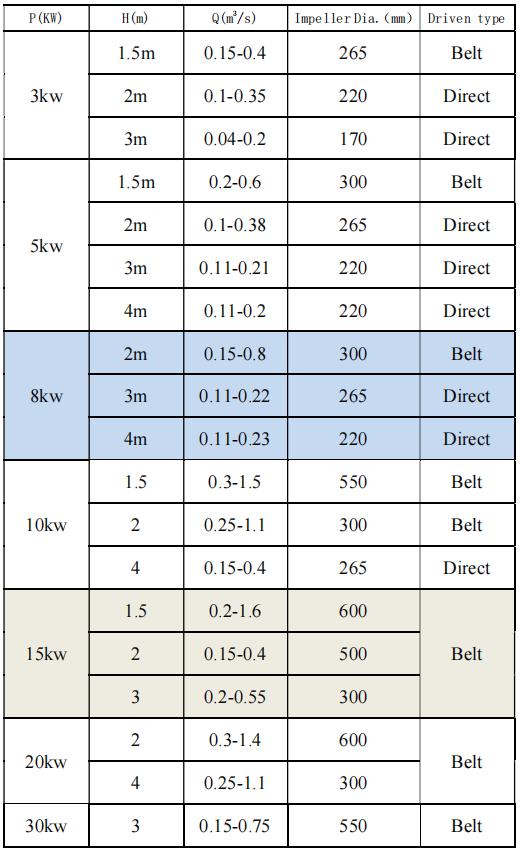

Paramètres techniques

Photo du produit

Conception de la chambre à vortex d'entrée

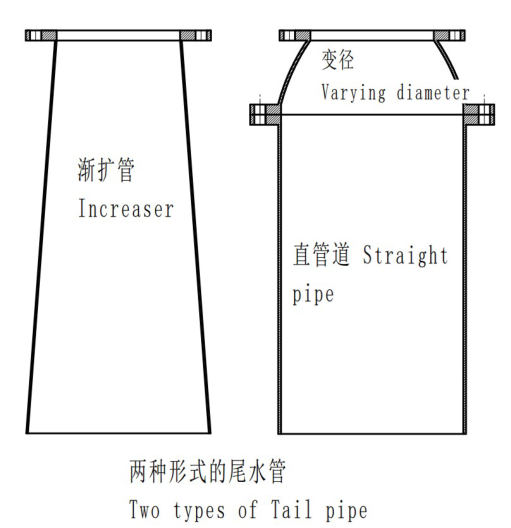

La figure ci-dessous illustre deux types de tuyaux d'échappement. Les tuyaux à diamètre variable et les tuyaux droits sont plus faciles à réaliser. En général, le diamètre maximal du tuyau d'échappement doit être de 1,5 à 2 fois supérieur au diamètre de la roue.

Le tuyau d'échappement à expansion progressive est présenté comme suit :

Il existe deux types de construction à expansion progressive : le type soudé et le type préfabriqué.

Le soudage du tube d'aspiration est aisé. Il est recommandé d'opter autant que possible pour une structure soudée. Lors du calcul de la hauteur du tube d'aspiration soudé, il faut tenir compte du fait que la sortie d'eau sera immergée de 20 à 30 cm.

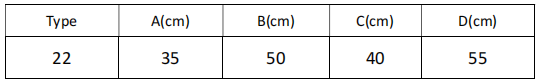

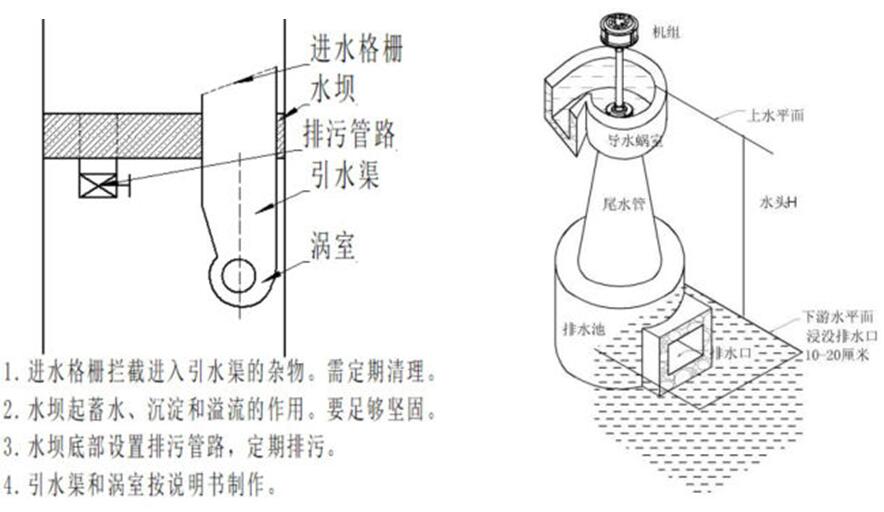

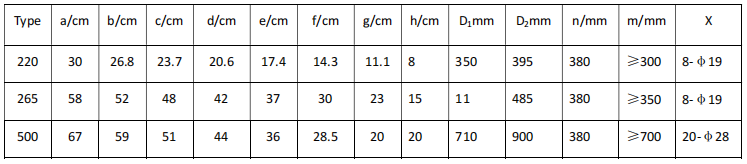

Sélectionnez la volute appropriée en fonction de la turbine axiale. Découpez un modèle de volute dans du papier rigide en utilisant les paramètres du tableau suivant. Construisez une volute en béton à l'aide de briques et de béton. Toute fuite de la volute est à proscrire.

Pour éviter les pertes hydrauliques, la surface de la volute doit être aussi lisse que possible.

Principaux paramètres géométriques de la chambre à vortex d'entrée

Dessin d'une volute axiale

1. La grille d'entrée empêche les débris de pénétrer dans le canal d'admission. Un nettoyage régulier est nécessaire.

2. Le barrage sert de réservoir d'eau ; les dispositifs de retenue et de déversoir doivent être suffisamment robustes.

3. Le fond du barrage doit être muni d'une canalisation de drainage pour un drainage régulier.

4. Le canal d'entrée et la chambre à vortex doivent être réalisés conformément aux instructions.

5. La profondeur d'immersion du tube d'aspiration ne doit pas être inférieure à 20 cm.

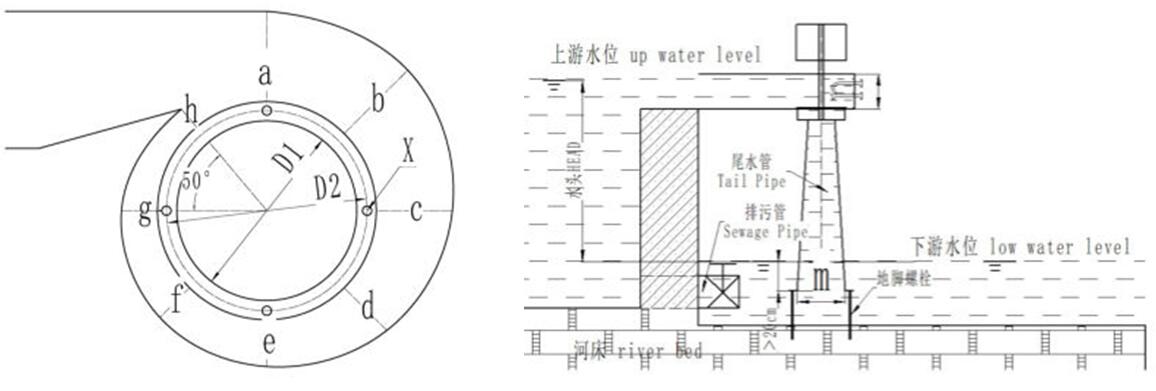

tube de tirage

Le tube d'aspiration peut être réalisé par soudure à partir de tôles d'acier ou construit en briques et en béton. Nous recommandons l'utilisation d'un tube d'aspiration soudé. Lors du calcul de la hauteur du tube d'aspiration soudé, il est impératif de veiller à ce que la sortie d'eau soit immergée de 20 à 30 cm.

Nous présentons ici la construction d'un conduit d'évacuation en brique et en béton. On commence par fabriquer un moule en bois pour le conduit et la sortie. Pour faciliter le démoulage, le moule est recouvert de papier ou de plastique. On obtient ainsi une surface lisse pour le conduit. Les dimensions principales du conduit et de la sortie sont indiquées ci-dessous.

Dimensions principales du tube de tirage et du module de sortie

Ensuite, construisez un bloc de briques autour du moule du tube d'aspiration. Appliquez une couche de béton de 5 à 10 cm d'épaisseur sur les briques. Retirez l'aube directrice fixe de la microturbine axiale et fixez-la sur le tube d'aspiration. Pour garantir le bon fonctionnement de la turbine, l'aube directrice doit être parfaitement verticale, comme illustré sur la figure ci-dessous. Afin de minimiser les pertes hydrauliques, la surface du tube d'aspiration doit être aussi lisse que possible.

Dimensions du tube de tirage et du module de sortie

Retirez le module lorsque le béton est ferme. La prise du béton prend généralement de 6 à 7 jours. Après le retrait du module, vérifiez l'absence de fuites. Les fuites doivent être colmatées avant l'installation du turbogénérateur. Installez le turbogénérateur sur les aubes fixes et maintenez-le horizontalement à l'aide d'une corde ou d'un fil de fer.

turbine axiale installée

Photo de l'usine

Contactez-nous

ALife Solar Technology Co., Ltd.

Téléphone/WhatsApp/WeChat : +86 13023538686

E-mail: gavin@alifesolar.com

Bâtiment 36, Hongqiao Xinyuan, district de Chongchuan, ville de Nantong, Chine

www.alifesolar.com